The increasing demand for product electrification across all industries necessitates faster product development turnaround times. To meet this demand, iNetic has made significant investments in advanced prototyping facilities, ensuring precise control and reliable early-stage development of key e-machine components and tooling.

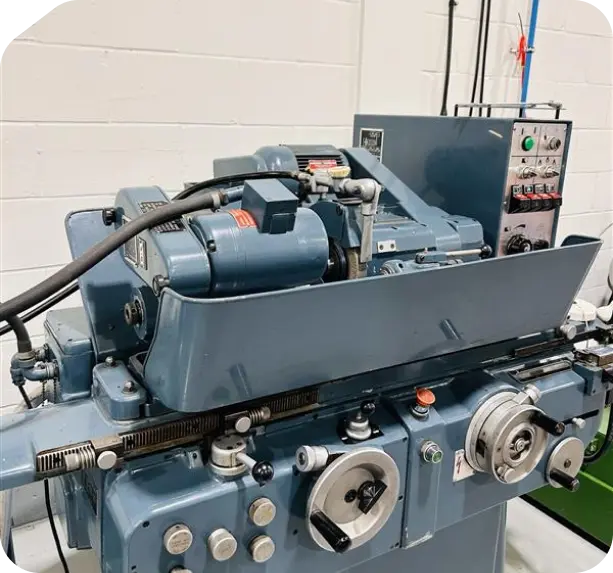

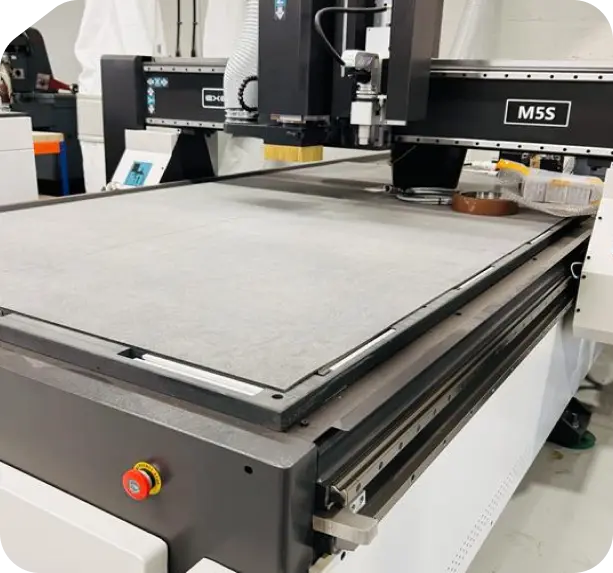

Our workshop is equipped with state-of-the-art facilities, including automatic grinding, honing, CNC milling, CNC turning, and multi-axis CNC capabilities. These resources enable us to efficiently manage the manufacturing of intricate components and tooling, ensuring high-quality outcomes and rapid development cycles. By leveraging these advanced technologies, iNetic ensures that every stage of product development is meticulously controlled, from initial concept through to final production.