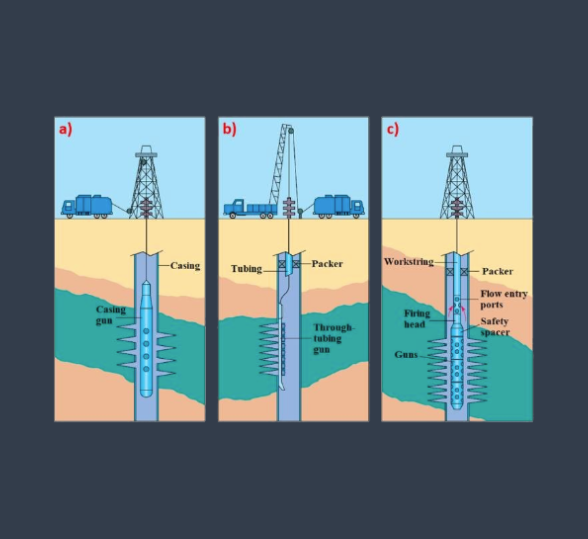

Downhole perforation tools are used for well completion. They puncture holes in the casing or liner, which creates a channel between the pay zone and the wellbore resulting in a clean channel for easy flow. It is critical that the perforated holes are debris free to allow for efficient fluid flow.

There are many different types of perforation methods such as bullet gun, abrasive, water jets and shaped charge. These utilise either explosive chemical reactions to perforate the wellbore liner or high-pressured hydraulics fluid to abrase the liner and form the flow channels. The method that our motor is designed for is for perforation through drilling or mechanically puncturing holes into the wellbore liner with mechanical penetration.