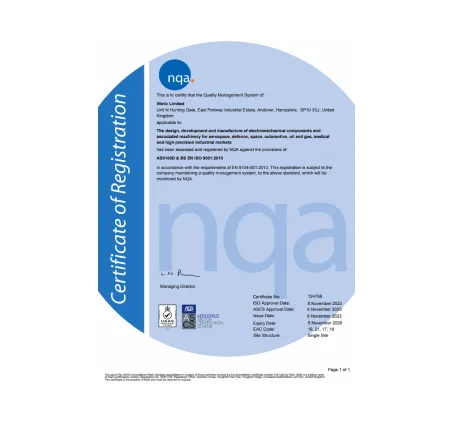

At iNetic, quality is the core of our operation. As an AS9100-certified company, we uphold the highest standards in design and manufacturing of Exploration products. meeting the stringent standards of the aerospace, defense, and security industries. Our robust quality assurance framework ensures reliability and consistency, supported by industry-leading practices that continuously refine our processes to exceed customer expectations.

Comprehensive Quality Assurance Measures

iNetic employs a wide range of quality assurance measures to ensure that every product we deliver meets stringent industry standards:

- First Article Inspection (FAI): We conducting thorough first article inspections to validate that our products meet all customer-specific requirements before full production begins.

- Basic Electrical Testing: Resistance, inductance, and other electrical characteristics are rigorously tested to ensure they meet the required specifications.

- Rigorous Testing: Our products undergo extensive electrical and mechanical testing, including AC/DC surge, hipot, corona, back EMF, dynamic balance, and more, ensuring they meet or exceed all required specifications.

- Dimensional Accuracy: Utilizing CMM dimensional analysis and magnified visual inspections, we ensure that all mechanical components adhere to precise dimensional requirements.

- Performance Testing: We conduct performance testing such as dynamometer (torque-speed) and detent torque (torque ripple) to verify the operational reliability of our products.

- Special Processes: We manage and monitor special processes with precision to ensure consistent quality across all projects.

- Corrective and Preventive Actions (CAPA): We proactively address non-conformances with root cause analysis and failure analysis, ensuring that issues are resolved promptly and future occurrences are prevented.

- Customer-Focused Inspection: We offer customer source inspection and maintain open communication with our clients throughout the production process to ensure their specific needs are met.

- Continuous Improvement: At iNetIC, we are dedicated to continuous improvement, constantly refining our processes to enhance quality and efficiency.

Traceability and Reporting: Every part we produce is fully traceable, and we provide detailed reporting, including CAPA, root cause analysis, and failure analysis, to keep our customers informed at every step.